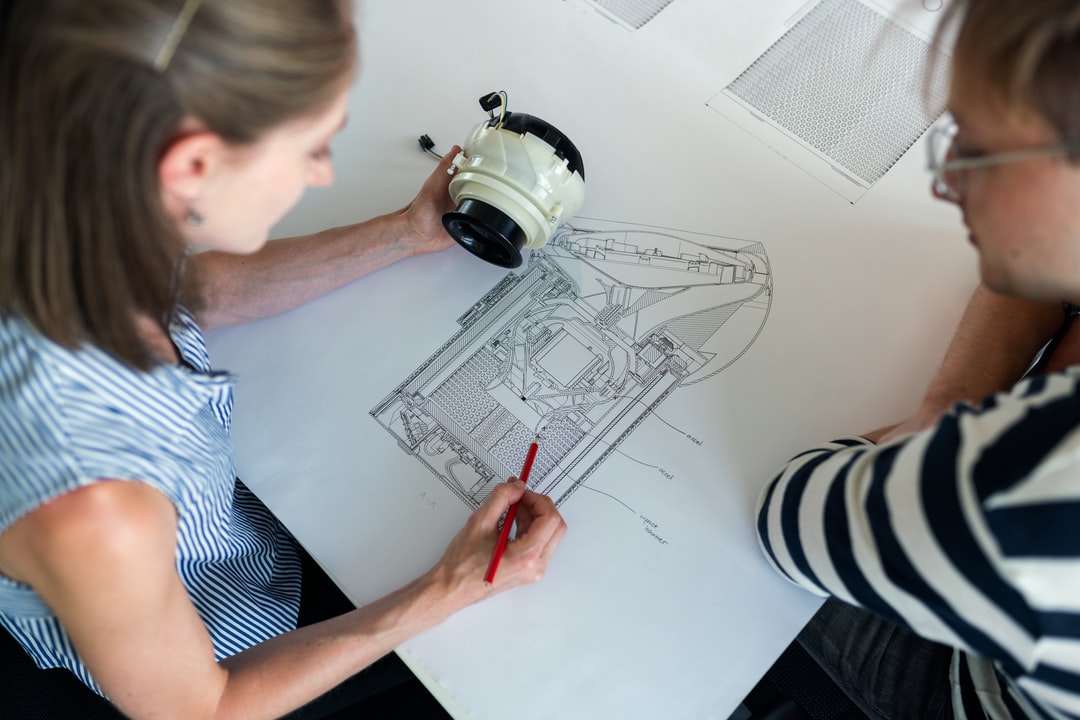

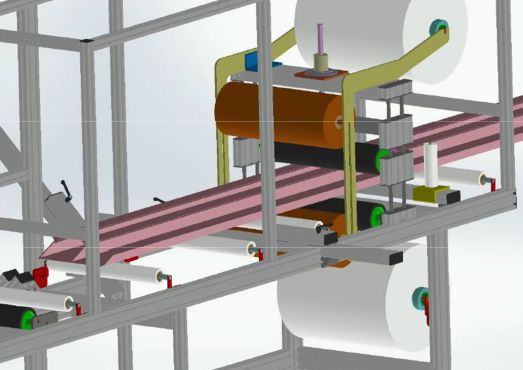

Machine Functionality

Applying protective tape to aluminum profiles and features automated operation with manual control options.

To meet the needs of an aluminum finishing factory, a specialized machine applies a low-density polyethylene adhesive tape to protect the surface finish of architectural aluminum profiles. This tape, also known as foil or film, is evenly applied along the full length and around all four sides of the profiles.

Operation is automated, with each aluminum bar's feeding stopping once it is fully covered. Feeding resumes only after the next bar is presented by the operator to the driving rolls. A foot switch allows the operator to momentarily halt profile movement, enabling them to cut the protective tape between profiles and separate them by pushing the finished profile aside. This process is assisted by another worker positioned at the opposite end of the typically six-meter-long aluminum profile bar.